Maintaining track of the temperature of the stator windings in electric generators, stator RTD sensors are a sort of temperature sensor. The turbine's stator, which is fixed, contains the windings that transform the magnetic field's motion into electricity.

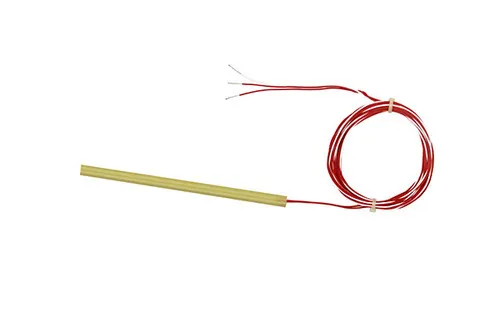

Resistance Temperature Detector, or RTD, is a term used for a sensor which detects temperature by observing variations in resistance. A thin platinum, nickel, or copper wire or film is wrapped around a ceramic or crystal substrate to create the stator RTD sensor. The wire's resistance increases with temperature, and it is this variation in resist that is used to determine the temperature.

Stator RTD sensors are important because they serve early warning systems for overheating, avoiding injury to the generator. Insulation break down brought on by warming can result in shorts in the circuit and other difficulties. The stator RTD sensor can alert the engine controls to take corrective action, such as reducing the load on the generator or shutting it down totally, by keeping track of the temperature of the windings of the stator.